Did anyone ever say “Always Check Your Measuring Implements!” to you?

If you have ever built something and it doesn’t work out just right, maybe you should check your measuring implements. There are several other things you can check too, but that is beyond the scope of this tip.

What is a Measuring Implement

Simply speaking, a measuring implement is a device that allows you to take a number and its units and convert it into a physically observable property, like distance, angle, mass, etc. To help you better understand, it could be a ruler, a tape measure, a scale, a protractor, calipers, a level, a dial indicator, etc.

Example Application

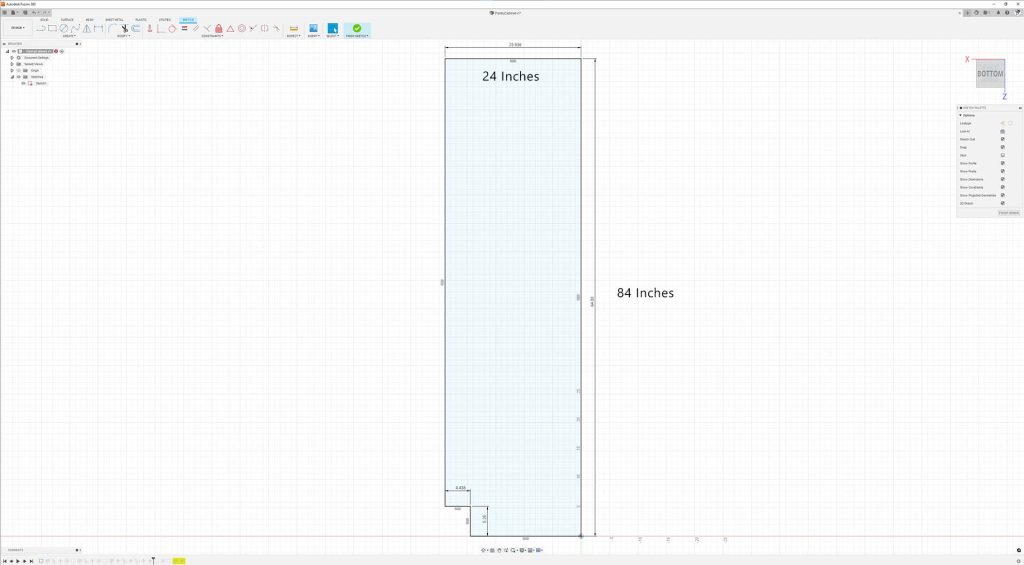

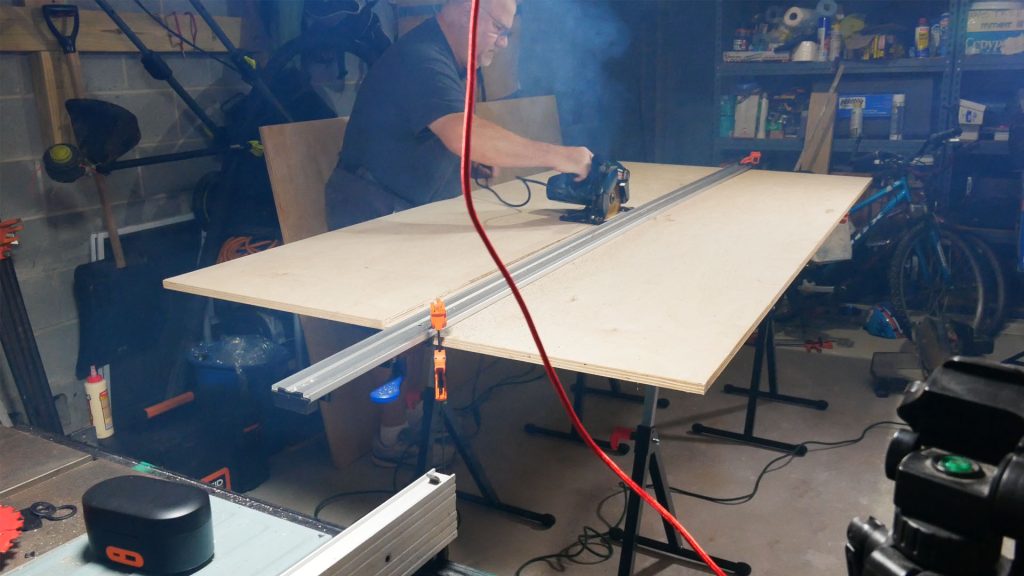

Perhaps you’re building a cabinet like I did. You sketched out your plans on paper and you’re ready to make your first cut. My plans called for 6 pieces cut from a 4×8 sheet of 3/4-inch plywood. So, I grabbed my favorite tape measure, which is a Craftsman 25′ tape, and began making my marks. I primarily used this tape measure, but I also used my Empire combination square. Little did I realize I just complicated things.

Tip – Use the Same one from Beginning to End

My dad, and other tradespeople and woodworkers, always told me whatever tape I use, stick with it from beginning to end of my project. He said that not every tape measure is built the same. If you switch between tape measures, you increase the risk of encountering different results.

Tip – Always Check your Tapes before you Start your Day

Ok, so I have to use the same tape from beginning to end. But, what about when I am up on a scaffold taking a measurement? Then I yell that number down to my crew mate and they cut based on my callout? To overcome this, you want to check your tapes at the beginning of the day. Why at the beginning of the day? You grab a tape and start using it. What if you grabbed a different tape? The same procedure might be applied after taking a lunch break.

To check the tapes, you can pull them from a good reference point and line them up together. Look for differences from the start to the finish. Check the hook of the tape as this is supposed to slide for both inside and outside measurements to account for the thickness of the hook itself.

Tip – Compare to Diverse Implements

This may sound like it is getting out of hand. But, let’s say you got a bad batch of tapes and you compare them all to each other and say you’re good. In reality, you only verified that they are a match. You didn’t check that they are valid. You can take a 1/2/3 block used by machinists and measure that it is 1-inch, 2-inches, and 3-inches. A combination square or a framing square could also be used to measure along the tape. But, don’t stop there. Continue to reference all of your implements, including your speed square, depth gauges, etc. If any of them do not agree, you need a solid and verifiable reference.

Tip – Reference Measurement

Government entities, like Weights and Measures, have devices to accurately measure things for calibration purposes. I’m not saying that you need to invest in sophisticated equipment but it is worth purchasing some good machinists references. These include Calibration Blocks, 1/2/3 Blocks, Setup Blocks, and many other types of references. These are typically machined down to the thousands of an inch tolerance and S.T.P. (Standard Temperature and Pressure). Their accuracy and tolerances are so good that those tolerances can be considered exact measurements for a framer building a home. Tighter tolerances would be required for someone building an engine. There is an entire science in measuring and determining accuracy and uncertainty.

Uncertainty

The study of uncertainty is what led to the common knowledge of taking three measurements of anything that you measure. Always start from the same position, like resetting your calipers to zero and retaking the measurement. And if you want to up it even further before hitting diminishing returns, you take 10 measurements. This practice helps to weed out factors that you might not otherwise consider, like:

- How were you standing when you took the measurement?

- Do you favor one side of a pencil mark, the middle, or the other side?

- Are you pulling the tape measure taut or leaving a little slack?

- Are you holding the tape measure parallel to the workpiece being measured?

When is Enough Enough

Seriously, when is enough ENOUGH? You have to pick what is right for you. We do this all the time in our everyday lives. Oh, I’ll drive my car with this crack in my windshield until next month. I will buy new steel-toe boots later as you are walking and the steel toe is going to fall out soon. We manage risk every day for ourselves.

You have to determine what your risk level is for these things. Not doing anything will cost money. But, doing something about it will also cost money.

What is your Trigger Point

I prefer things to be good enough. Let’s say I compare two tape measures and one is off by 1/8 of an inch. Well, which one is off, and is it 1/8 of an inch? And, how long have I been using this tape measure? Chances are you will know as something won’t line up, consistently.

But, if you place two tapes side by side and visually they look ok, that might be your good enough.

Next Steps

Adopt some form of measuring and implement a verification procedure. Perform this periodically but don’t overdue it. But, don’t assume every tool you buy is perfect, even though we expect it.

“As an Amazon Associate I earn from qualifying purchases.”

Video Credits:

Video Production: U Do It™️ Studios a Division of No Cheese Records® LLC All Rights Reserved.

Do It Yourself Build a Shed Series

To learn more about this series check out the DIY Build a Shed Series here.

Picked out for you

How big should your makerspace be? – By U Do It

Do It Yourself Build a Shed – The DIY Experience – By U Do It

Incredible Tool: Do It Yourself Build a Shed – Bilt Hard Plate Compactor – By U Do It

Do It Yourself Build a Shed – Where to Start – By U Do It

Do It Yourself Build a Shed – Planning and Estimating – By U Do It

Protect your Cabinets with Drawer and Shelf Liner – By U Do It

Our Kitchen Storage Is Lacking – DIY Pantry Cabinet – By U Do It

The First Cut – DIY Pantry Cabinet Part 2 – By U Do It

Do It Yourself or Hire a Contractor – By U Do It

Garage door wont close unless I hold the button down – By U Do It

How to Install a Door Lever for a Bedroom – By U Do It

Save money by rebuilding your grill burners – By U Do It